China Classification Society (CCS) Visited Pacific International Lines (PIL) and SDTR Marine Pte Ltd and signed a Momorandum of Cooperation

With relatively low fuel prices and an existing advanced network of bunkering stations in many ports around the world, LNG has become a very attractive option for new buildings and retrofit projects. Most ME-C engines in the Marine Engine Programme of MAN Energy Solutions can be offered as dual-fuel ME-Gl gas engines, thereby ensuring that all ship types can be converted to dual-fuel operation.

Furthermore, these can be applied together with four-stroke, dual-fuel, auxiliary MAN generator sets, such as MAN 23/30DF, MAN 28/32DF and MAN 35/44DF, which can also run on gas, covering a wide range of electrical loads.

1. Importance of limiting methane emissions on LNG-fuelled vessels – current regulations

One particular issue that has recently become a significant concern is the so-called methane slip from gas engines. Since methane (CH4) comprises 85–95% of natural gas and has a global warming potential (GWP) equal to 84–86 times the CO2 equivalent over a 20-year time frame, or 28–34 times the CO2 equivalent over a 100-year time frame, it is clear that if no measures are taken, the expansion of LNG as an alternative marine fuel could be hindered.

The IMO, EU, research organisations, and shipowners who have chosen to actively pursue decarbonisation and lower emissions of their fleets, have all started raising the issue and pushing for a resolution. From 2025, the FuelEU Maritime regulation will require ships calling EU ports to gradually reduce the well-to-wake greenhouse gas (GHG) intensity, including methane slip, of fuels and energy used. IMO is expected to introduce a goal-based marine fuel standard regulating the phased reduction of the marine fuel GHG intensity (also including methane slip) from 2027.

2. Parameters affecting methane emissions – slip versus engine blowdown

Typically, methane emissions from dual-fuel engines can be attributed to the unavoidable phenomenon of methane slip which occurs when the engine operates on gas, or to the blowdown of unburned fuel to the ambient environment when gas operation ceases. The origin of these methane emissions is explained below.

The former category includes methane escaping from the combustion chamber during the combustion process. Dual-fuel engines operating according to the Diesel combustion cycle, such as the ME-GI engine, have an inherently lower methane slip when compared to low-pressure gas engines. This is because gaseous fuel is injected into a very small volume, with the piston close to top dead centre and then ignited instantaneously. The injection of pilot fuel shortly precedes the gas injection, initiating the ignition and creating the right conditions for an efficient and swift gas combustion.

Currently, MAN Energy Solutions guarantees a methane slip for the ME-GI engine in the range of 0.2–0.28 g/kWh for an engine load between 25–100%, which is the lowest on the market.

The term engine blowdown refers to venting of pressurised methane fuel from the engine volume and the piping downstream the gas valve train (GVT) directly to the atmosphere. When the engine stops running on gas, the blowdown procedure is activated as part of the engine operational sequence to ensure that pressurised gas is removed from the engine and piping before initiating the gas purging process with nitrogen.

Blowdown is considered a part of the fugitive emissions and despite being very small compared to other emissions types it contributes to the total amount of methane emitted during the vessel’s operation.

MAN Energy Solutions is actively looking into new ways to limit methane emissions from both slip and fugitive slip related to operations even further. Some of the solutions which are offered, or are under development, are discussed in the next section.

3. New solutions provide additional measures for emission management

Apart from ensuring a particularly efficient combustion process with a high efficiency for the ME-GI engine, which is naturally accompanied by a superior fuel economy, MAN Energy Solutions is also looking into other ways to improve emissions with a special focus on methane emissions.

Methane slip is mainly tackled indirectly by adjusting the engine performance parameters and optimising the fuel-burning process, and also by using a shaft generator together with the main engine. In power take-off (PTO) mode, the shaft generator can operate parallel to auxiliary engines (gensets) when coupled with a frequency converter. An interesting feature considering the methane emissions reduction, since auxiliary engines feature both a higher fuel consumption (inherent to four-stroke, Otto-cycle engines), and a higher methane slip during operation. Therefore, limiting operation to a reasonable extent, and covering the required vessel hotel load with the main engine, is clearly advantageous from an economic and environmental point of view.

In addition, MAN Energy Solutions is currently investigating a novel gas return system with the purpose of catching up to 95% of the amount of gas emitted during the engine blowdown procedure. The main idea behind the design is to return unburned gas to a buffer tank instead of sending it to the vent mast and emitting it into the atmosphere. Next, the gas is supplied to suitable downstream consumers, such as the ship boiler or auxiliary engines (gensets), where it may be used to produce thermal or electrical energy, thereby increasing the overall efficiency and reducing methane emissions. This system is under development and can be offered as an optional feature for new ME-GI projects in collaboration with shipyards.

With EcoEGR, gas tuning is possible which further optimises the ME-GI engine and further reduces the carbon intensity.

The next section elaborates on emission data, covering methane slip, and blowdown-related figures. Furthermore, a comparison is made between a medium-sized ME-GI engine, typically used for the propulsion of LNG carriers (5G70ME-C10.5-GI), and one of the biggest engines (10G95ME-C10.5-GI) which may be installed on ultra large container vessels (ULCVs).

4. Quantifying emissions data from two different ME-GI engine sizes

To properly quantify methane emissions from the ME-GI engine, data concerning two different engine sizes, namely the 10G95ME-C10.5-GI and the smaller 5G70ME-C10.5-GI, were obtained from respective CEAS engine data reports, and real engine operating profiles.

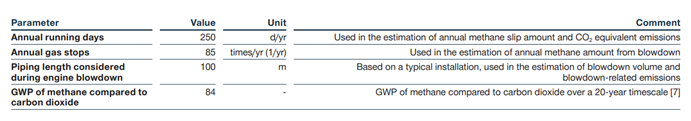

First, the assumptions in Table 1 were made to establish a common basis for the comparison. The data reflects common dual-fuel engine operating data from real installations.

Table 1: Typical operating profile characteristics for an ME-GI engine

The number of gas stops per year varies for different ship types and depends highly on the operating profile. The value shown in Table 1 represents an average vessel equipped with an ME-GI engine with very frequent port calls. However, regardless of the number of gas stops used for the estimations that follow, it is crucial to understand potential gas savings for both engine operation (slip) and blowdown.

Additionally, data for the combustion of methane fuel and pilot oil were used for the emissions calculations.

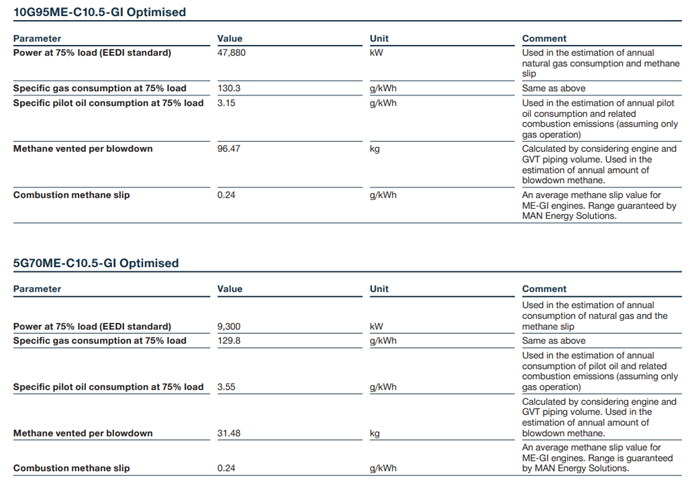

Table 2 contains other information that was considered for the estimation of methane emissions from the two ME-GI engine sizes and vessels.

Table 2: Engine-specific data for two different MAN B&W ME-GI engines

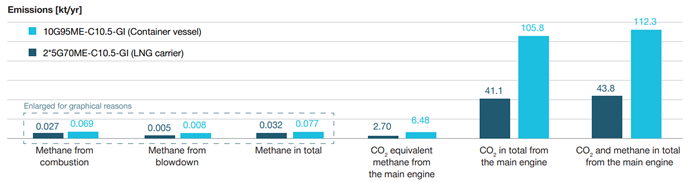

The methane emitted annually and the total CO2-equivalent for a container vessel and an LNG carrier (twin-engine) in Fig. 1 are based on the data in Table 2.

Fig. 1: Methane and CO2 equivalent emissions from a container vessel engine (10G95ME-C10.5-GI) and from a twin-engine LNG carrier installation (2*5G70ME-C10.5-GI)

By observing Fig. 1, it is evident that the exhaust gas amount from the container vessel is higher owing to the larger engine volume compared to the LNG carrier. It has to be mentioned that, unlike other vessels, LNG carriers have a twin-engine propulsion system and this has been considered when estimating emission values in Fig. 1.

This means that the absolute values in Table 2 for a single engine were multiplied by a factor of 2 to attain the vessel data in Fig. 1. The contribution of total methane emissions to the total global warming potential is not so prevalent. The results illustrate that even though methane is 84 times more potent than carbon dioxide as a greenhouse gas (short-term global warming potential), the overall methane emissions account for only 6–7% of the total emissions GW potential for both engines that were studied (based on CO2 equivalent units). This is in line with the argument that the ME-GI engine inherently features particularly low methane emissions. Nonetheless, it is still our intention to further optimise the system, and rather important to support the industry in this regulated greenhouse gas emission environment by providing the necessary solutions.

Furthermore, in the LNG carrier installation, the amount of methane emitted during simultaneous blowdown for both engines (worst-case scenario) accounts for approximately 17% (~1/5) of the total vented amount. For the container vessel engine, the respective percentage is 11%. This shows that although more methane is emitted during combustion due to slip, it is crucial to limit the amount of gas fuel vented to the atmosphere during a gas stop/engine blowdown. Limiting the number of gas stops (especially on the high seas), or implementing a gas return system, which enables reuse of almost the entire blowdown fuel amount instead of wasting it, are potential methods that could reduce this amount. Especially the latter, which is currently under development as an optional feature for ME-GI engines, becomes very attractive both in terms of environmental protection and energy integration. Although the total amount of methane wasted during blowdown represents less than 0.1% w/w of the hourly gas fuel consumption of the ME-GI engine, it is still relevant to use it for other applications, rather than sending it to the vent mast.

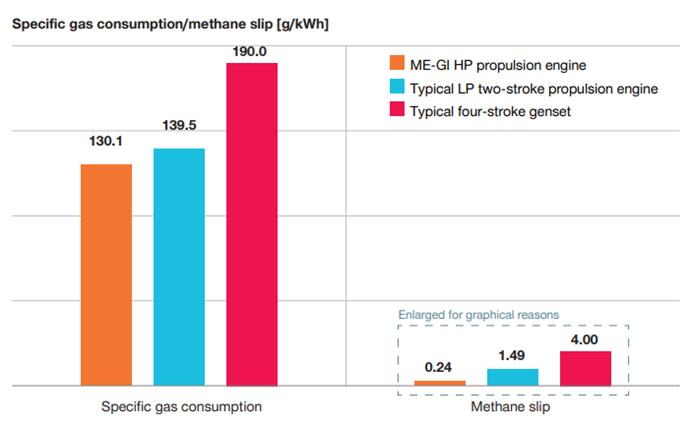

Fig. 2 shows specific gas consumption and methane slip levels for different dual-fuel engines. A comparison is thereby established of a high-pressure (HP) dual-fuel ME-GI engine, a low-pressure (LP) dual-fuel two-stroke gas engine, and a four-stroke auxiliary gas engine.

Fig. 2: Specific gas consumptions and methane emissions for different engine types

Note that data for the LP two-stroke engine and the four-stroke genset are not linked to a single engine design, but reflect a more generic market trend. Further, they are given on specific (relative) terms to be independent of the size differences between the engines examined.

It is also worth mentioning that MAN Energy Solutions is actively looking into ways to reduce the methane slip from both the LP two-stroke propulsion engine (ME-GA) and four-stroke main and auxiliary engines (gensets). As already mentioned, EGR is the primary technology of choice for the ME-GA engine, while four-stroke engines can benefit from the application of oxidation catalysts, such as the IMOKAT II, for reducing the slip.

By observing Fig. 2, the advantages of the ME-GI relative to other dual-fuel gas engine technologies become evident. The ME-GI boasts 7% and 32% reductions in specific gas fuel consumption when compared to an LP two-stroke engine and a four-stroke genset, respectively. More importantly, the combustion-related slip is only 16% of that of an LP two-stroke engine, and 6% of that of a genset. With these superior characteristics, not only does the ME-GI offer a better fuel economy, but it also becomes more attractive from an environmental point of view, given the significance of cutting methane emissions as mentioned above.

5. Conclusion

This paper provides insight into the high-pressure dual-fuel gas engine developed by MAN Energy Solutions, namely the optimised ME-GI, the operation and associated emissions with a special focus on methane emissions.

Methane is a greenhouse gas, multiple times more potent than carbon dioxide, and therefore the release into the atmosphere has to be limited. To achieve that, both the naturally occurring, combustion-related methane slip amount, and the blowdown-related methane amount emitted after every gas stop, need to be controlled.

The findings in this paper for two different ME-GI engine sizes point out the conclusion that the ME-GI is the most efficient marine dual-fuel engine, as it offers a superior fuel economy compared to alternative designs or technologies. Furthermore, it features the lowest emissions compared to any other engine. Even so, MAN Energy Solutions is actively pursuing new ways of cutting down methane emissions from the ME-GI engine. These include the extensive use of PTO, the installation of proven after-treatment technologies like the EGR, and the development of a novel gas return system, capable of saving up to 95% of the gas that would otherwise be vented to the atmosphere during engine blowdown, among others.

There is no doubt that the ME-GI engine has an important role to play in the future of the maritime industry, even more so when renewable bio-based, or synthetic gas production becomes more relevant.

Source: MAN